News

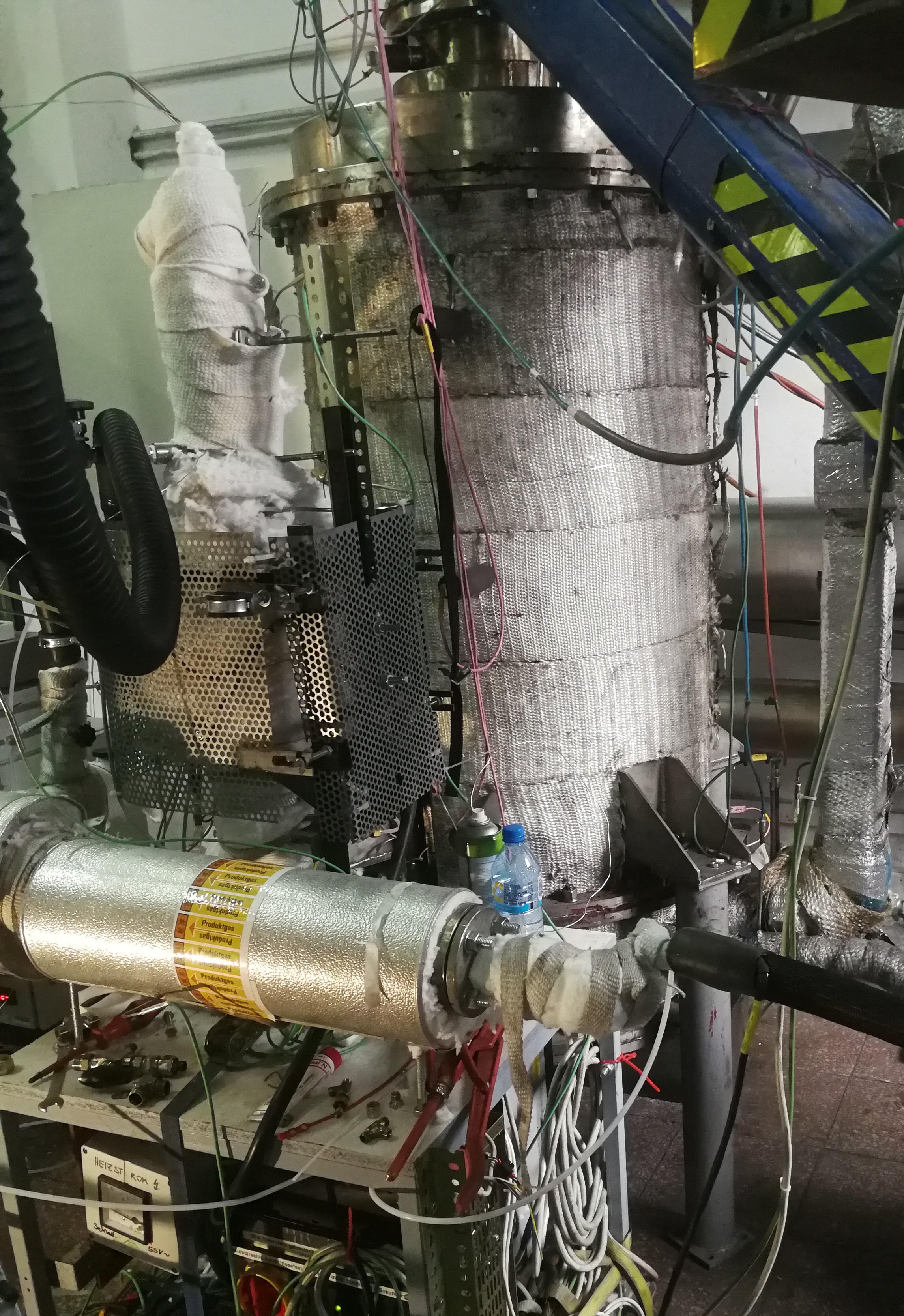

At the air-blown Kajot gasifier at IEN in Warsaw BEST conducted studies on the sulfur removal process in parallel pursuing two objectives:

- the removal of all sulfur compounds enabling long-term operation studies of a SOFC-stack, via pilot scale setup

- the observation of the desulfurization process under real gas condition of the gasifier (e.g. kinetic behavior of H2S-, and COS-removal or formation reactions), via small scale setup

Figure 1 Schematic view of experimental setup for real syngas adsorption tests

Pilot-scale long-term sulfur removal: although the main gas components changed during the operation of the gasifier, neither H2S nor COS were detected at the outlet. Since equilibrium constants of H2S and COS for ZnO adsorption at 350°C are quite high, a complete removal of these pollutants is possible at high residence times. The tests confirmed, that both, COS and H2S, can be removed simultaneously at 350°C and 240 h-1 GHSV by ZnO adsorption to clean gas concentrations below 1 ppm. It should be considered that low GHSV values had been chosen to ensure a proper SOFC-operation. These GHSV values are not suitable for an economically feasible real scale operation since very large column volumes would be required.

Small-scale setup: higher COS concentration was found in the adsorption outlet stream than both raw syngas and sulfur gas mixture for all the time. That suggests COS production occurs in the adsorption column under dry conditions. Atakul et al.,also found that COS formed during H2S removal on dolomite, possibly due to the presence of CO or CO2. Higher H2S concentration may lead to increased reaction kinetics of CO/CO2 and H2S that produce COS. Subsequent systematic experiments under lab-conditions, employing synthetic gas mixtures confirmed the findings.

More News

News